Feature

●[15% High-Modulus Carbon Fiber Filled Nylon]-The material of iSANGHU Industrial PA6 CF comes from Germany, is a composite filament material that is 15% Chopped carbon fiber filled and based on Nylon 6 (Polyamide 6). This carbon fiber-reinforced material greatly enhances the materials overall performance and reduces the risk of warping during printing.

●[Excellent Mechanical Properties]-iSANGHUs PA6-CF has exceptional mechanical properties due to its advanced formulation using high-quality Nylon and chopped carbon fibers. Our Smart Fiber Enhanced Technology ensures optimal dispersion and distribution of carbon fibers during extrusion, resulting in a mesh skeleton structure that bears most of the load transferred by the material matrix to improve mechanical properties, heat resistance, and dimensional stability.

●[Stable tolerance & Good Layer Adhesion]-Advanced CCD diameter measuring and self-adaptive control system in manufacturing ensure strict tolerances. Diameter 1.75mm, dimensional accuracy + / - 0.02 mm. The low shrinkage and stable printing dimensions make the fusion between the layers very good to obtain an even better-bridging result.

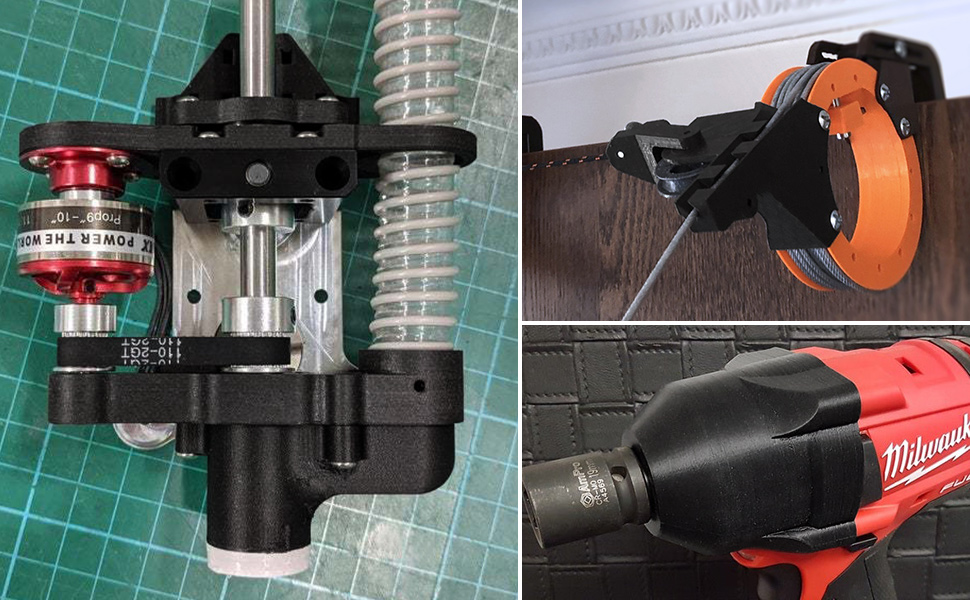

●[Wide Industrial Applications]-The carbon fiber filament 3d printing materials enable lightweight and durability, suitable for applications requiring torsional, tensile, and impact strength such as functional prototypes, tools, fixtures, end-use parts, pump impellers, mechanical gears, precision, and engineering components, widely used in robots, drones, automotive, aerospace and Medical industry.

●[Tips for Printing]-The PA6-CF is highly abrasive and can wear out and clog stock 0.4mm brass nozzles rapidly. A larger diameter (0.6mm or more), abrasion-resistant hardened steel or ruby nozzles nozzle is highly recommended, and keep your nozzles clean between every several prints or so. The recommended drying temperature is 80 ℃ for 10 hours in a blast drying oven, or 90 ℃ for 12 hours on a heat bed before printing. Print Temp: 260°C - 300°C, Bed Temp: 80°C - 100°C, Print Speed: 30-80mm/s.

●[Vacuum Sealed & Moisture Free]-Completely drying for 24 hours before packaging and vacuum sealed with desiccants in a transparent bag to effectively protect the filament from moisture enabling much smoother and more stable printing. Please remember to put it back into the bag timely after use to maintain excellent printing performance.

[Asa Cf-matte Black ASA-CF Filament 1KG]

[Petg Cf-indigo Blue Colored PETG-CF Filament]

[Abs Cf-matte Black ABS-CF Filament 1KG]

[Pla Cf-matte Black PLA-CF Filament 1KG]

[Petg Cf-army Green,stone Gray,mocha Brown,amethyst Colored PETG-CF Filament]

[Petg Cf-matte Black PETG-CF Filament 1KG]

[Petg Cf-crimson Red Colored PETG-CF Filament]

[Petg Cf-frosted Orange Colored PETG-CF Filament]

[Pa6 Cf-matte Black PA6-CF Filament 1KG]

[Petg Cf-chestnut Brown Colored PETG-CF Filament]

[Petg Cf-army Green Colored PETG-CF Filament]

[Pa12 Cf-matte Black PA12-CF Filament 1KG]

Description